Quality Process

Quality is an important parameter for us. It helps us in meeting stringent requirements of high-tenacity multi-filament yarn as it is used in high speed stitching of a wide variety of bags; besides in rope making, as cable fillers, in geo fabrics, in filters and in a wide range of general industrial applications. Ropes, bags, fabrics, nettings, all have to withstand the vagaries of weather, the drubbing of time and manhandling.

Quality from product to packaging

Our products undergo stringent quality checks at every stage. Our product is passed through our fully-equipped laboratory and is checked on various parameters like Denier, Tenacity, Linear Density, Spinnerets Checking, Broken Filament Test, and Twist per Meter, Air Velocity and Elongation at Brake. To check the breaking load, we have computerised testing machines specially designed pneumatic grips, controlled via advance software and a sophisticated programme with graphical views for depth evaluation results. We have a full-fledged separate laboratory equipped with all testing machines and equipment for checking products as per ASTM and ISO Standards. The laboratory rejects every piece that shows even a slight anomaly in the stipulated quality standard.

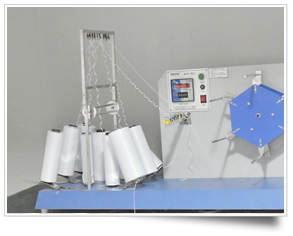

Laboratory Equipment Laboratory Equipment

- Computer controlled tensile testing machines

- QUV accelerated weathering tester - Q Lab, US

- Automated digital wrapped reel for denier determination

- Polarising projection microscope

- Digital stroboscopes

- Twist tester

- Yarn tension meter

- Thermo-anemometer with air flow

|